Heat Riser Valves and Manifold Heat Control Devices

Depending upon the type of engine you have and which manufacturer made it, these are essentially the same things. This device is usually a valve or flapper that diverts exhaust gas to a hot spot in the intake manifold underneath the carburetor. Sometimes the heat for the hot spot is provided by the engine's cooling water. Intake manifold heat for street-driven engines is good and necessary for good fuel distribution. Air flowing through the intake and especially vaporizing fuel will cool the intake manifold. On the highway, this would happen to a greater extent.

To get the utmost performance from a race car, the intake manifold needs to be as cold as possible but these cars usually don't run well year-round on the street. Street-driven engines work much better when heat is supplied to the intake manifold. If heat is causing problems with percolation in the carburetor, insulation between the manifold and the carb is a better choice than eliminating heat from the intake.

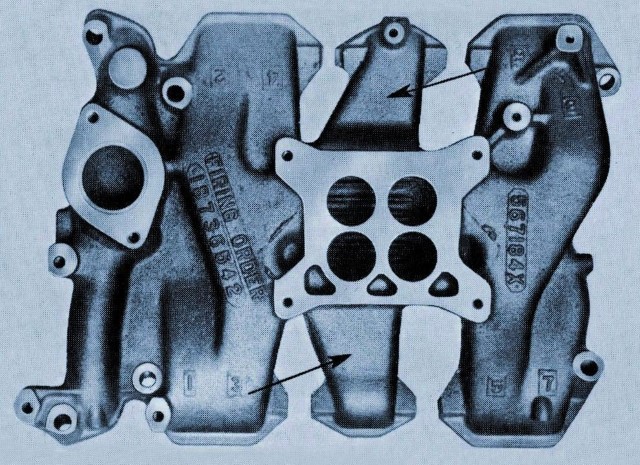

On an OEM V8 intake manifold, there typically is a cross-over passage (see arrows in photo above) that connects exhaust ports in each cylinder head. A thermostatically-controlled heat riser valve in one of the exhaust manifolds closes when the engine is cold to direct the exhaust flow from one cylinder head through the intake manifold. Once the heat riser valve opens, the flow through the cross-over passage becomes much smaller.

Propane and natural gas mono-fuel engines are supplied with a fully vaporized fuel so intake manifold heat is of no benefit. A cold intake manifold is a correct modification for these engines. However, blocking off only one of the exhaust ports allows the EGR system to remain functional to reduce NOx emissions.